Manufacturing Services for Any Project

Design & Engineering

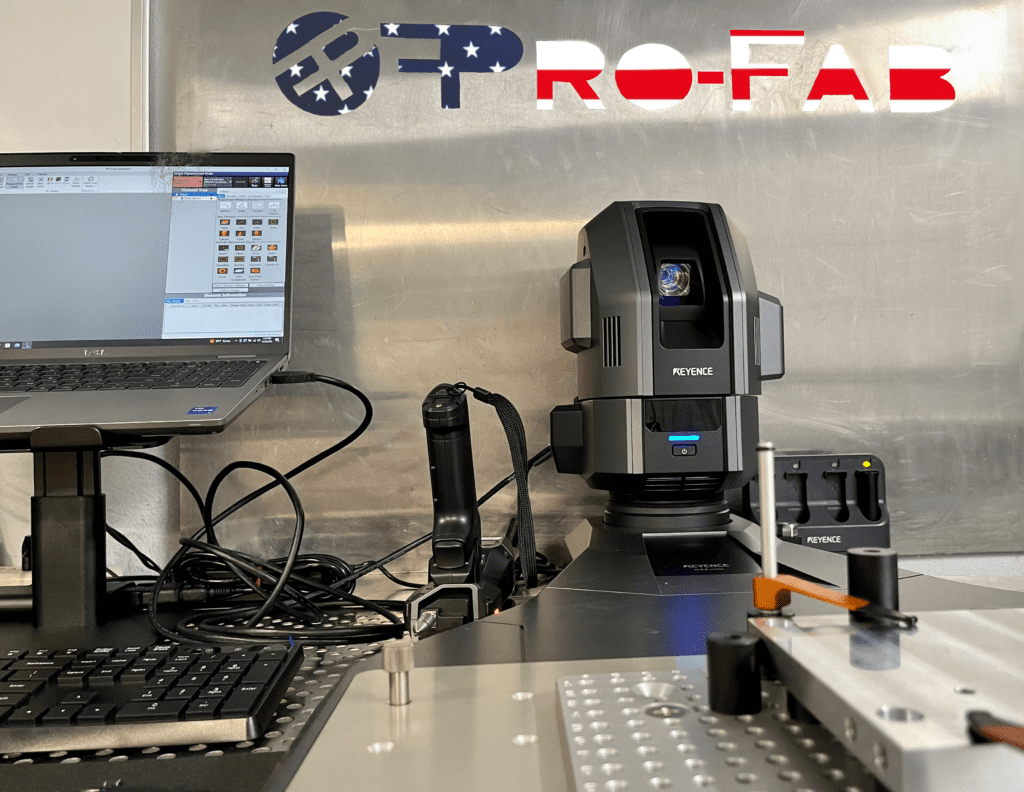

Quality Assurance

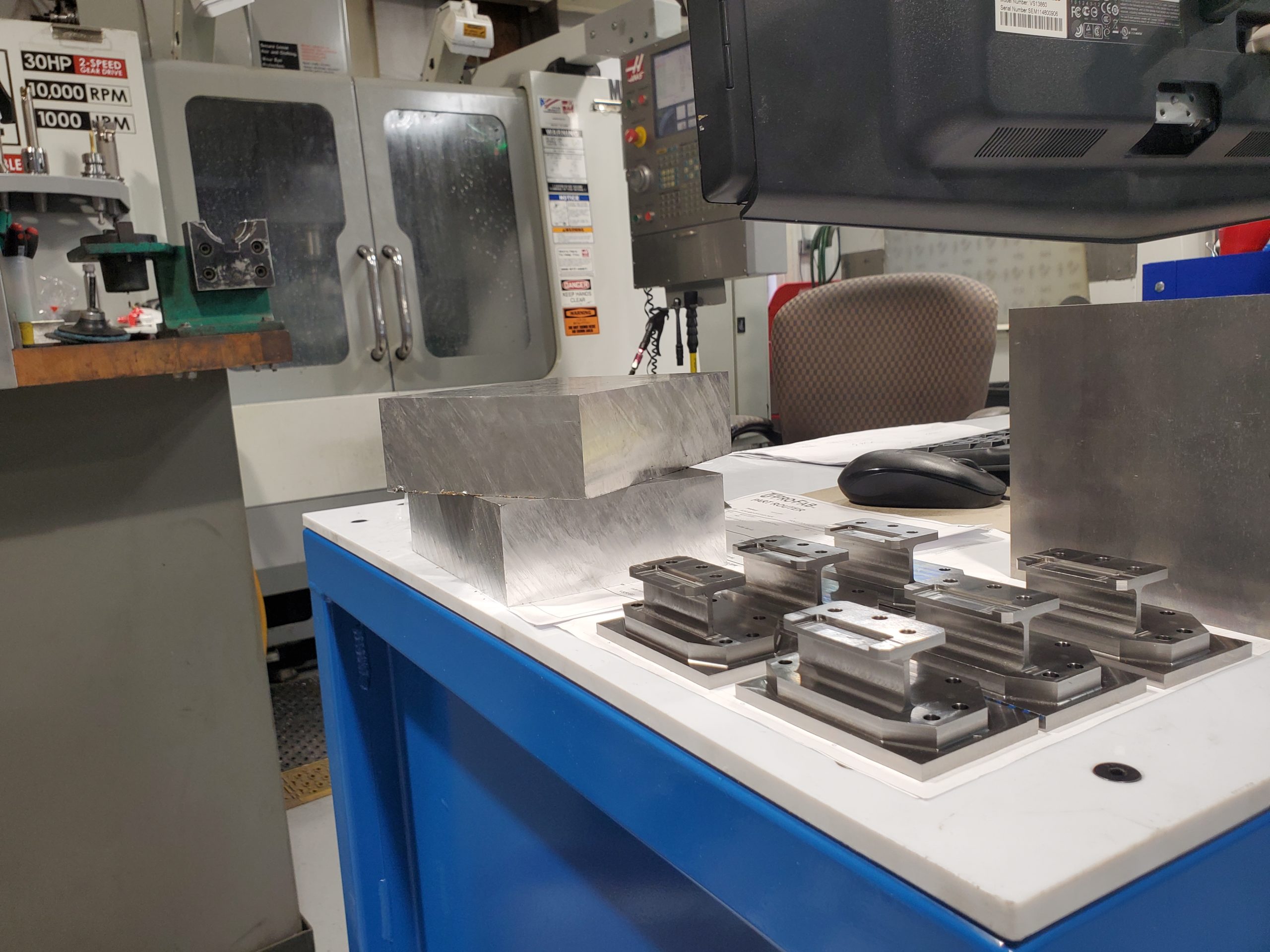

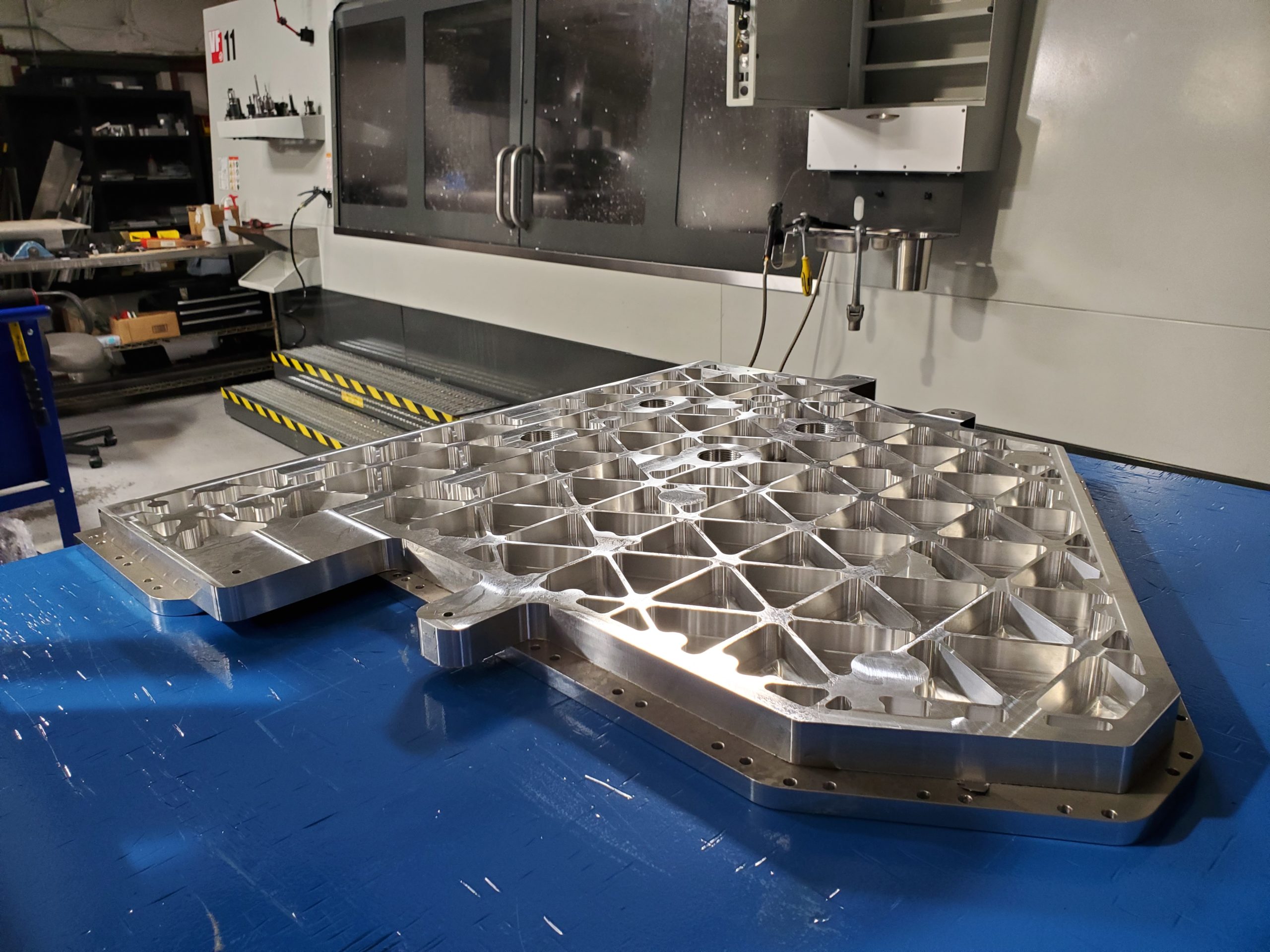

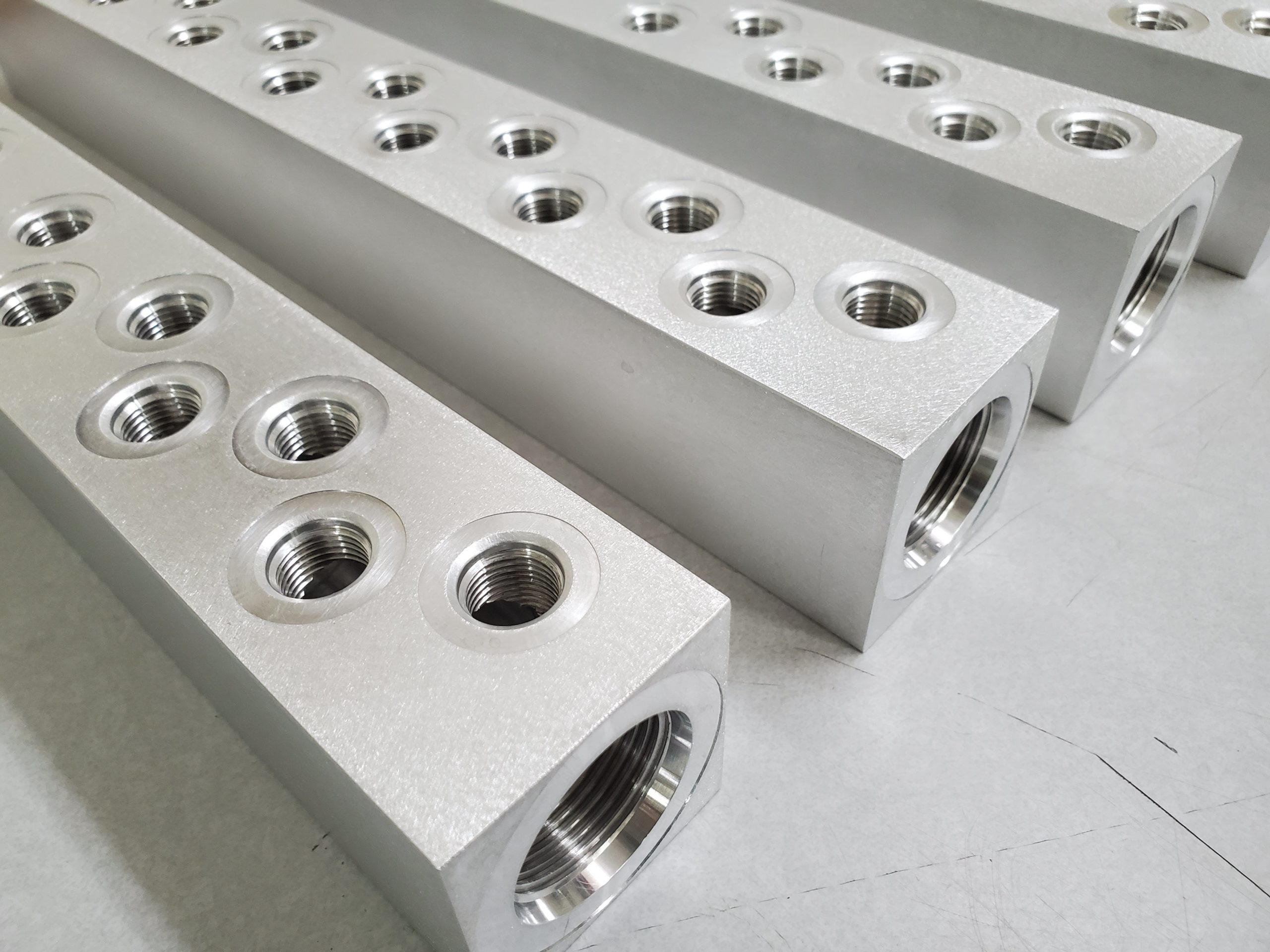

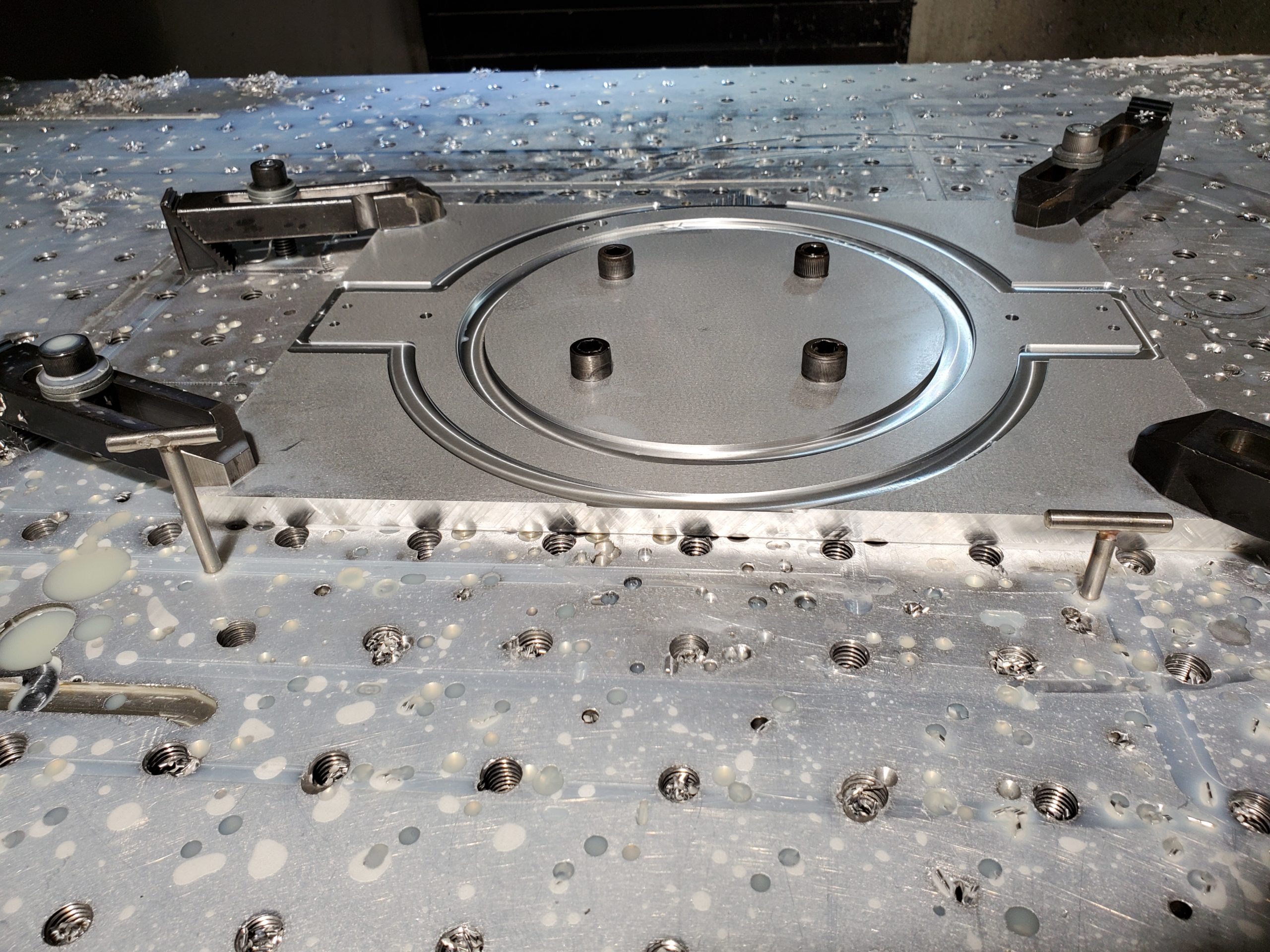

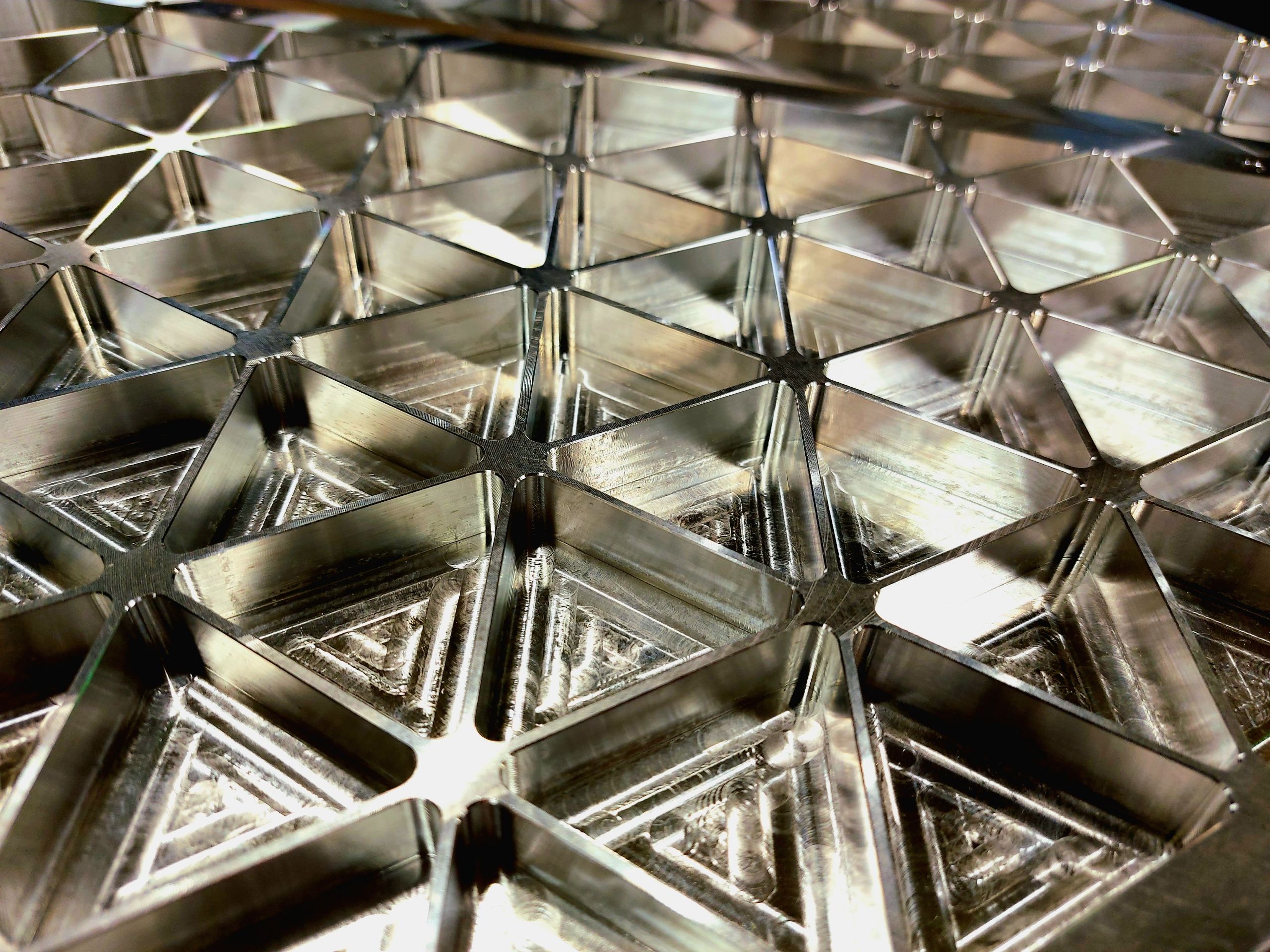

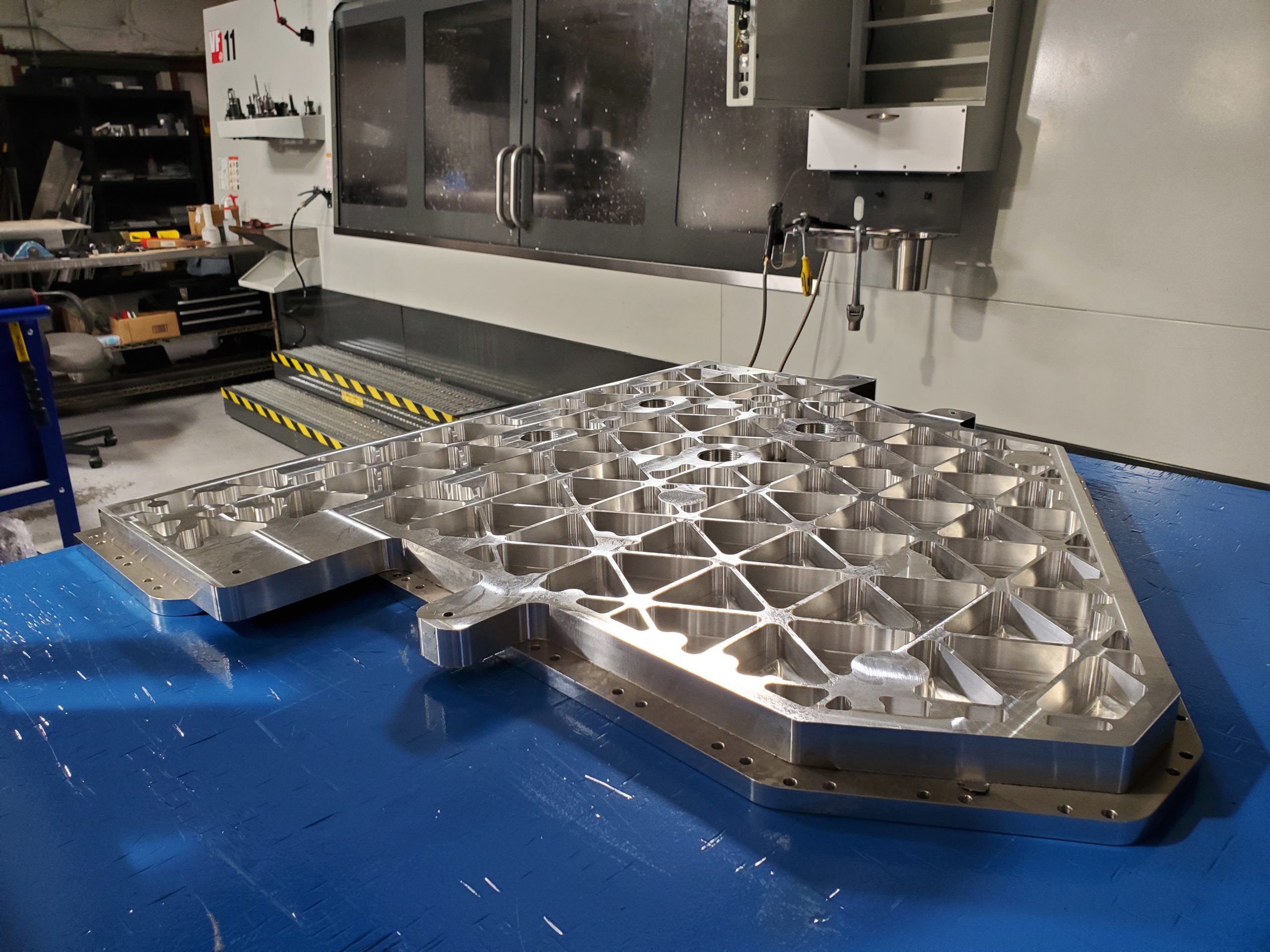

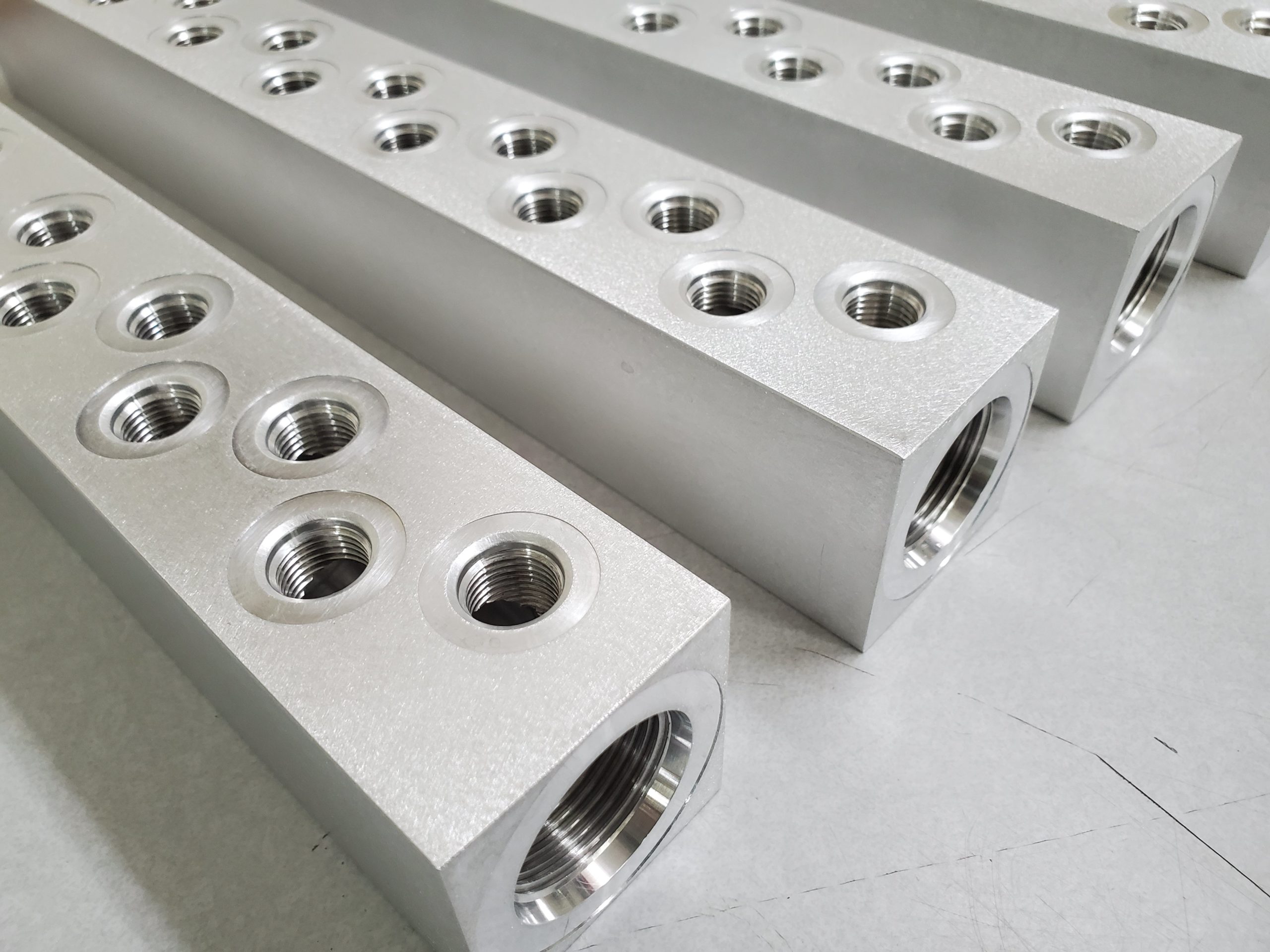

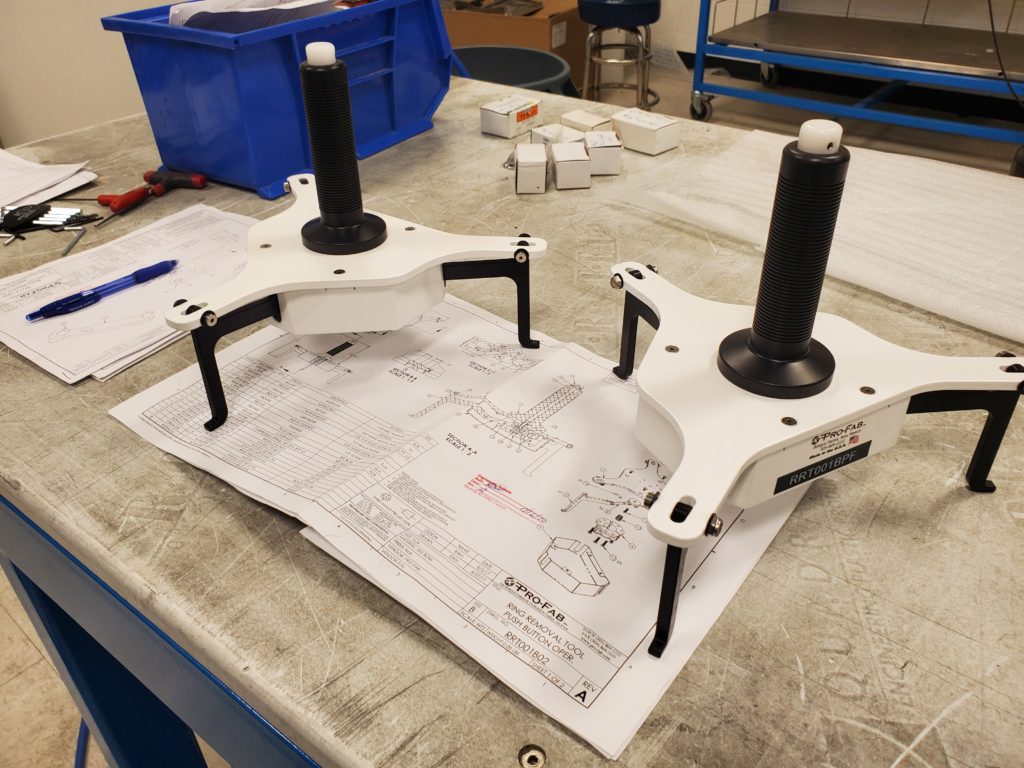

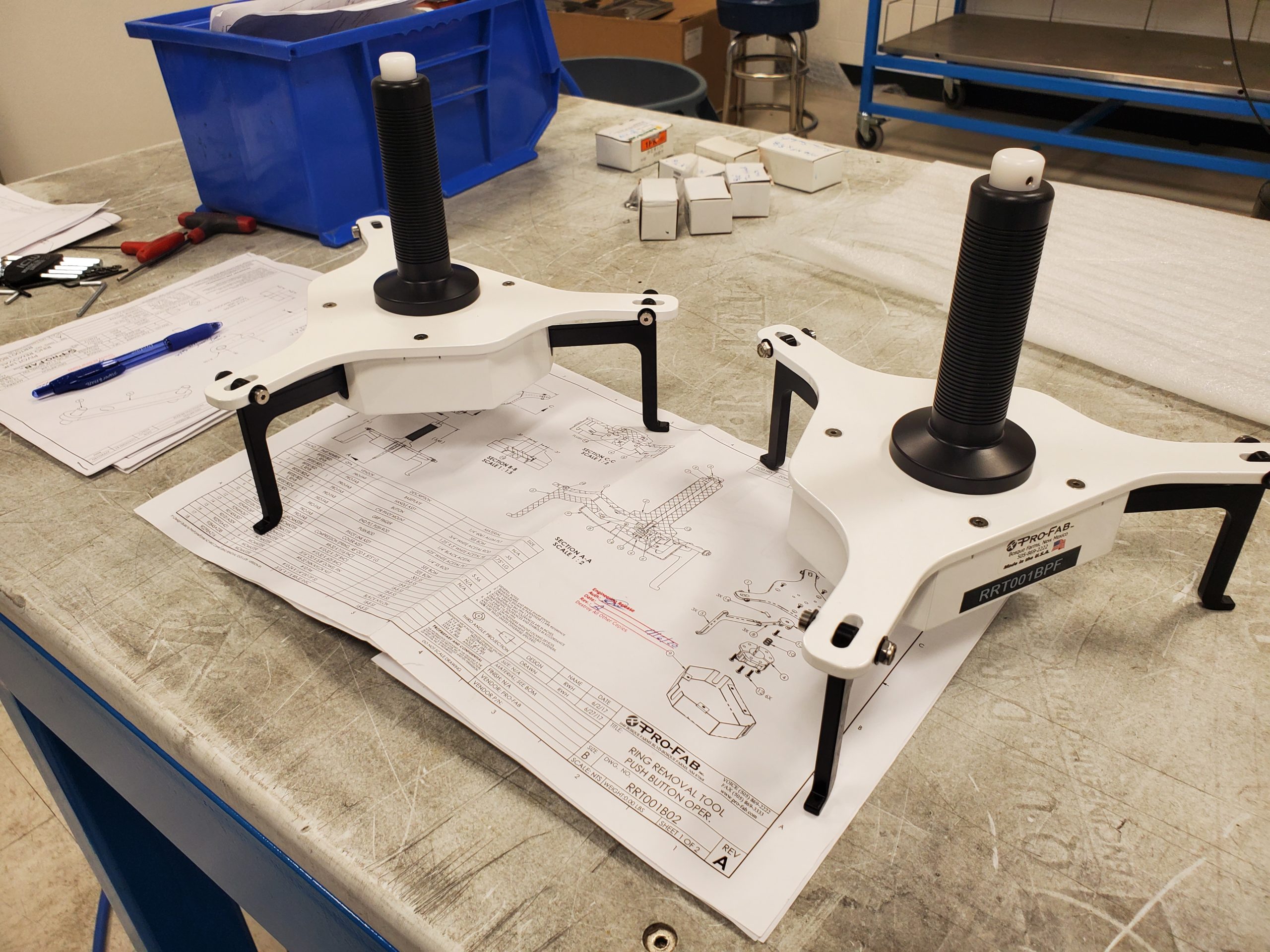

Machining

Pro-Fab uses cutting edge CNC equipment to machine parts for our customers. Our expert machinists are experienced in machining stainless steel, carbon steel, aluminum, and a variety of plastics to manufacture your products. Having machinists in house allows for seamless manufacturing and quality control. Many components we machine are used in larger assemblies that we manufacturer. We are ITAR registered to be able to handle any defense related needs.

Machine Shop Equipment and Capabilities

| MACHINE | USE | TRAVEL LIMITS |

|---|---|---|

| Hurco VMX42i with Inspection Probe | 3-Axis Milling | 42"X x 24"Y x 24"Z |

| Haas VF-11 | 3-Axis Milling | 120"X x 40"Y x 30"Z |

| Haas VF-6 | 3-Axis Milling | 64"X x 32"Y x 30"Z |

| Haas VF-4SS | 4-Axis Milling | 50"X x 20"Y x 25"Z |

| Haas VF-2 | 5-Axis Milling | 30"X x 16"Y x 20"Z |

| Haas VF-2 | 3-Axis Milling | 30"X x 16"Y x 20"Z |

| Haas Mini Mill | 3-Axis Milling | 16"X x 12"Y x 10"Z |

| AXYS Router | 3-Axis Milling | 48"X x 120"Y x 5"Z |

| Haas SL20 | Lathe/Turning | 10"OD x 10"L |

| Omax Maxiem 1530 Waterjet Cutter | Cutting | 120"X x 62"Y x 12"Z |

Machine Shop Equipment and Capabilities

| ALUMINUM | STAINLESS STEEL | PLASTIC | STEEL | OTHER METAL |

|---|---|---|---|---|

| 2024 | 303 | Acetal (Delrin) | Mild steel | Brass |

| 5052 | 304 | Polypropylene | Alloy steel | Copper |

| 6061 | 316 | ABS | Titanium | |

| 7075 | 17-4 | Polycarbonate | ||

| 420 | PVC | |||

| HDPE | ||||

| PTFE (Teflon) | ||||

| PEEK | ||||

| UHMW |

Machined Parts Finishing Options

| ALUMINUM | STAINLESS STEEL | STEEL |

|---|---|---|

| Anodized | Electropolished | Powder Coated |

| Hard Anodized | Passivated | Painted |

| Powder Coated | Brushed/Polished | Machined/Raw |

| Painted | Powder Coated | |

| Chemical Conversion | Painted | |

| Chemical Conversion | Machined/Raw | |

| Machined/Raw |

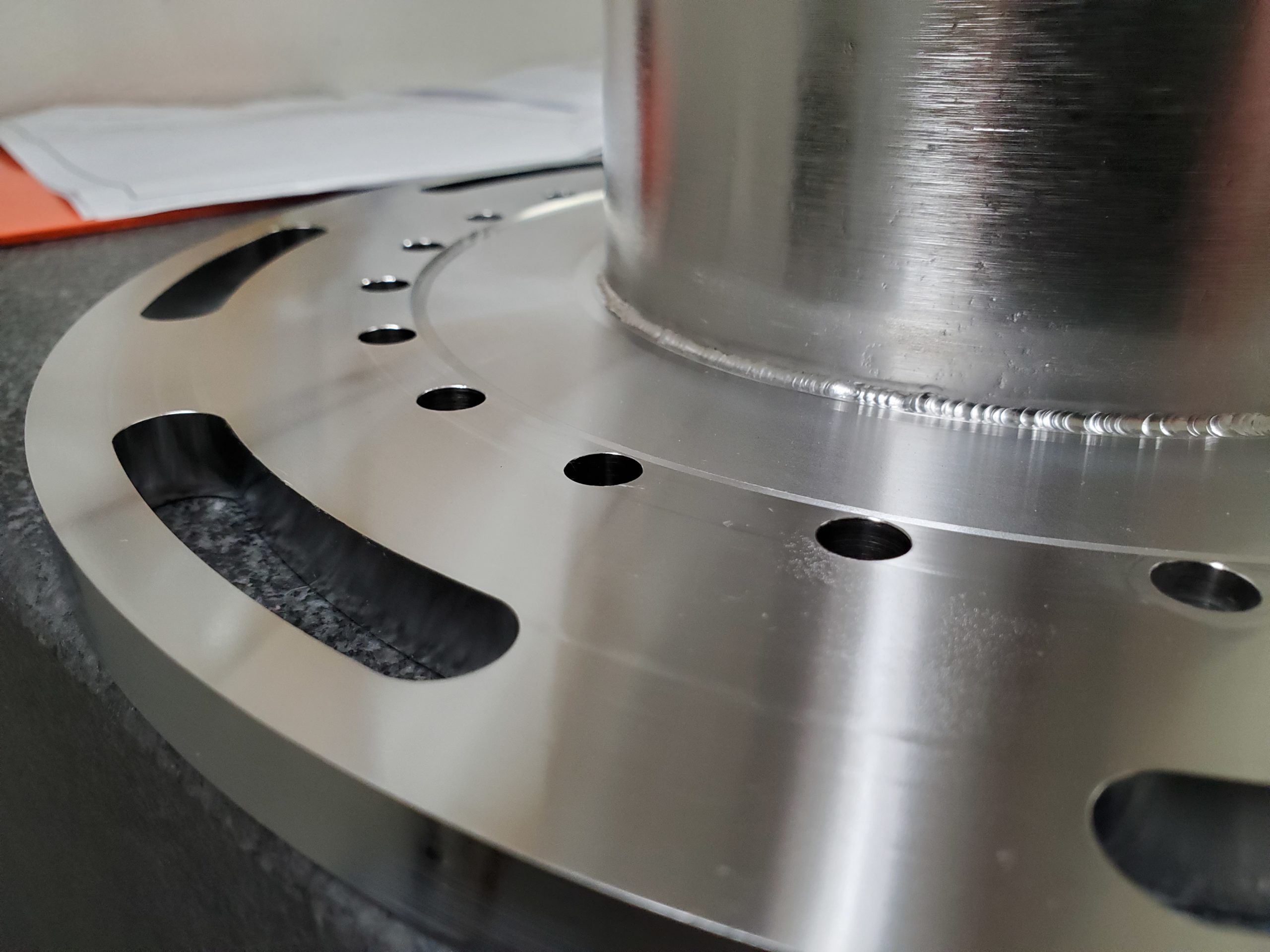

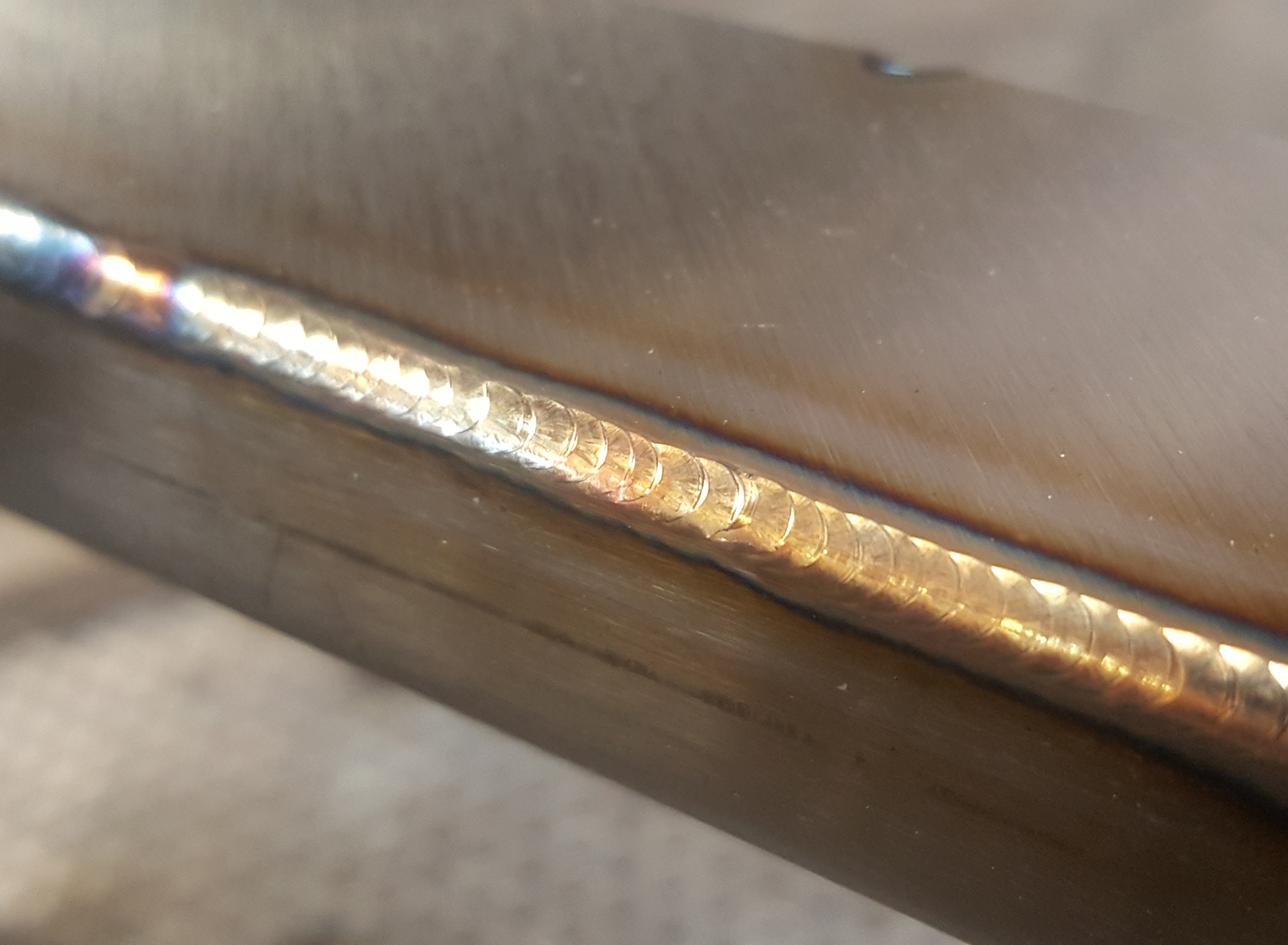

Welding

Pro-Fab has certified welders on site to weld aluminum, stainless steel, and mild steel. Pro-Fab design and manufactures material handling or transport products such as carts, cabinets, and fixtures for a variety of technical industries such as semiconductor manufacturing, pharmaceutical, and research and development projects. Pro-Fab machines and welds in-house: we do not outsource. Do you have a weldment that you need produced? Please consider Pro-Fab: we have produced hundreds of weldment over the years and would appreciate the chance to meet your custom welding and fabricating needs.

Pro-fab has certified welders for:

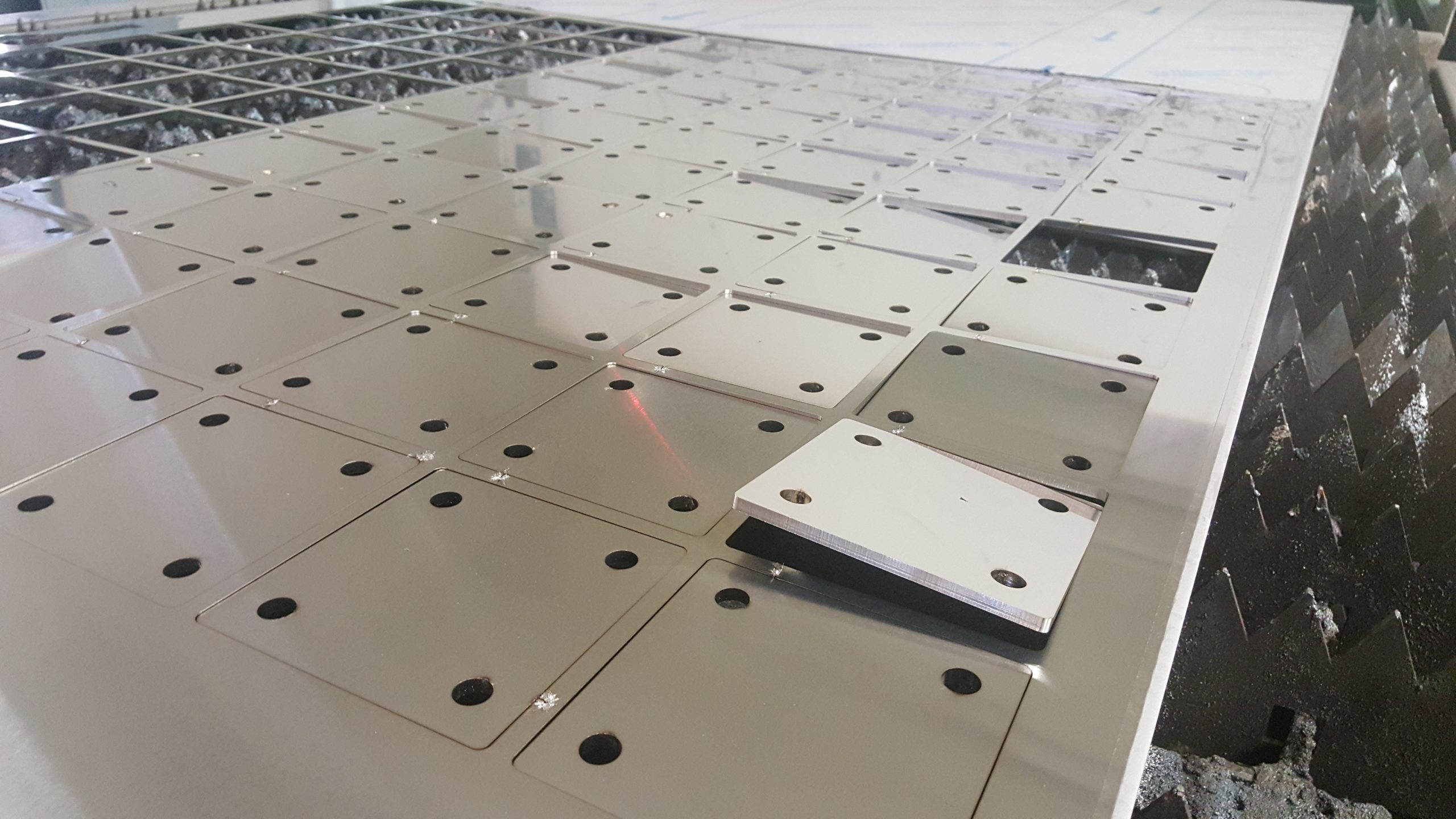

Sheet Metal

Pro-Fab utilizes sheet metal for a variety of custom fabrication projects for manufacturing facilities. Many of the carts, workstations, steps, and countless other projects we produce for our clients utilize sheet metal in some form. To streamline our fabrication production services we cut, punch and form our own sheet metal needs in-house. We have the equipment and experienced technical staff to produce the sheet metal to specs for all of the custom products we design and fabricate.

Sheet Metal Equipment & Capabilities

| MACHINE | USE | LIMITS |

|---|---|---|

| Mitsubishi 4kw CNC Laser | Cutting | 120"X x 60"Y x 1/2" thick |

| Wiedemann CNC Turret Punch | Punching | 120"X x 48"Y x 1/8" thick |

| Mitsubishi BH8525 CNC Press Brake | Forming | 102" Long, 94 Ton |

| Durma E30160 CNC Press Brake | Forming | 120" Long, 170 Ton |

| LVD 50 Ton Press Brake | Forming | 50" long, 50 Ton |

| Atlantic HYD-CNC Shear | Shearing | 120" long, 3/16" thick |

| 48" Slip Roll | Rolling | 48" wide x 1/8" thick |

| Pemsetter | Hardware | PEM studs and PEM nuts |

Common Materials in Sheet Metal

| ALUMINUM | STAINLESS STEEL | STEEL |

|---|---|---|

| 2024 up to 1/4" thick | 304 up to 1/2" thick | Mild steel up to 1/2" thick |

| 5052 up to 1/4" thick | 316 up to 1/2" thick | Alloy steel up to 1/2" thick |

| 6061 up to 1/4" thick | ||

| 7075 up to 1/4" thick |

Sheet Metal Parts Finishing Options

| ALUMINUM | STAINLESS STEEL | STEEL |

|---|---|---|

| Anodized | Electropolished | Powder Coated |

| Hard Anodized | Passivated | Painted |

| Powder Coated | Brushed/Polished | Raw |

| Painted | Powder Coated | |

| Chemical Conversion | Painted | |

| Alodine | Raw | |

| Raw |

Laser Cutting

Need laser cutting services for your metal parts? Upload your DXF files here and we’ll get right back to you with a quote on your parts. Laser cutting offers a high quality edge cut and tighter dimensional tolerances than other cutting methods. Standard materials are steel, stainless steel, and aluminum.

Common Materials in Laser Cutting

| ALUMINUM | STAINLESS STEEL | STEEL |

|---|---|---|

| 2024 up to 1/4" thick | 304 up to 1/2" thick | Mild steel up to 1/2" thick |

| 5052 up to 1/4" thick | 316 up to 1/2" thick | Alloy steel up to 1/2" thick |

| 6061 up to 1/4" thick | ||

| 7075 up to 1/4" thick |

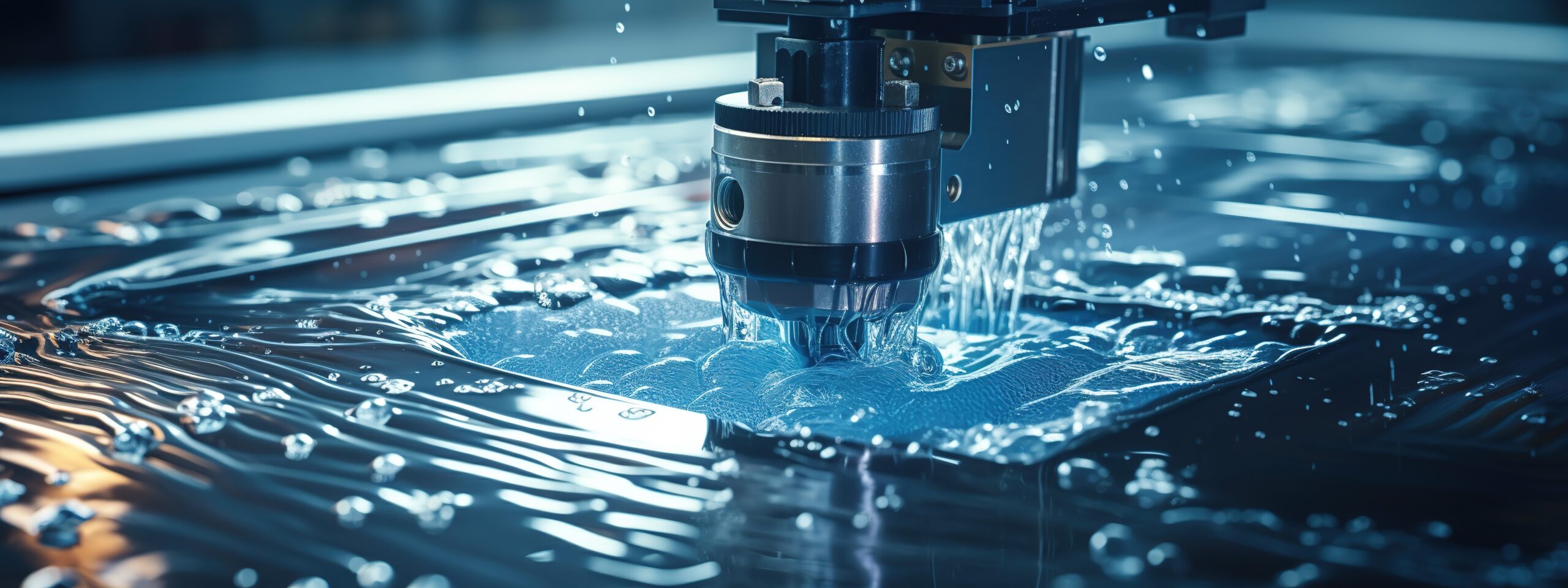

Waterjet Cutting

Cutting with a waterjet produces a smooth edge with no burn marks, cracking, or excess burrs. With a cutting envelope of 10'0" x 5'2" and +/- 0.003" linear position accuracy, we are able to support jobs ranging from prototype development to full-scale production. Upload your DXF files here to receive a quote on your parts. Water cutting offers options on a wide range of materials and thicknesses, from metals and composites to glass and plastics.

Common Materials in Laser Cutting

| ALUMINUM | STAINLESS STEEL | STEEL |

|---|---|---|

| 2024 up to 1/4" thick | 304 up to 1/2" thick | Mild steel up to 1/2" thick |

| 5052 up to 1/4" thick | 316 up to 1/2" thick | Alloy steel up to 1/2" thick |

| 6061 up to 1/4" thick | ||

| 7075 up to 1/4" thick |