Cleanroom and Industrial Safety Padding: What It Is and Why You Need It

Cleanroom and Industrial Safety Padding: What It Is and Why You Need It

Maintaining worker protection and contamination control is essential in industries such as semiconductor manufacturing, pharmaceuticals, and advanced technology production. One important solution that supports these goals is industrial safety padding. Facilities that implement industrial safety padding help protect employees from accidental contact with equipment while preserving cleanroom standards. High quality industrial safety padding improves workplace ergonomics, reduces fatigue, and supports operational efficiency. As maintenance tasks and production demands continue to increase, organizations are recognizing that industrial safety padding is a valuable investment in both employee well being and facility performance.

Understanding Industrial Safety Padding in Cleanroom Environments

Industrial safety padding protects production and maintenance workers from injuries caused by sharp corners, exposed edges, and rigid equipment surfaces. In controlled environments where employees frequently kneel, lean, or crawl under equipment, properly designed industrial safety padding provides cushioning that reduces impact injuries and physical strain. Many facilities rely on industrial safety padding to protect workers performing maintenance activities in uncomfortable or restricted spaces. These protective products can be installed temporarily or permanently to support safety while maintaining compliance with cleanroom contamination standards.

Common Industrial Safety Padding Products and Applications

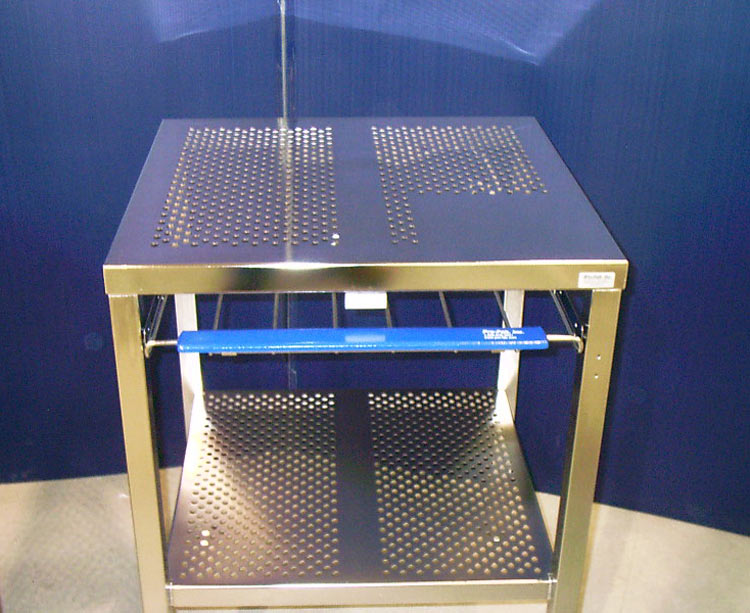

Facilities utilize several product types designed to improve safety and ergonomics through industrial safety padding. Popular solutions include ergonomic back pads that protect workers sliding under equipment, kneeling pads that provide cushioning during maintenance tasks, and wrist pads designed to support repetitive keyboard or mouse use. Corner and edge bump padding is another important form of industrial safety padding that helps prevent injuries in maintenance zones and production areas. Additional solutions such as cleanroom mouse pads, floor mats, and customized ergonomic products allow facilities to expand their use of industrial safety padding across multiple workstations and operational zones.

Materials and Design Features of Industrial Safety Padding

The performance and durability of industrial safety padding depend on the materials used during fabrication. Pro Fab manufactures padding using PVC coated nitrile or EVA closed cell foam that provides cushioning while maintaining a cleanable surface. This material selection allows industrial safety padding to resist contamination and maintain low particle shedding. The PVC coating also encapsulates exposed foam surfaces and allows manufacturers to apply silkscreen markings when required. Engineers can customize industrial safety padding using integrated rigid substrates to increase durability and extend product lifespan in environments exposed to frequent contact or heavier wear.

Installation, Mounting, and Performance Considerations

Proper installation ensures that industrial safety padding performs reliably in demanding production environments. Facilities often install permanently mounted industrial safety padding using cleanroom compatible hook and loop fasteners or industrial grade double sided tape. When substrates are integrated into the design, industrial safety padding can also include mechanical mounting options such as threaded inserts or mounting holes. Engineering teams carefully evaluate tolerance expectations because foam based products naturally contract during manufacturing. These considerations help ensure that industrial safety padding maintains its protective performance while fitting properly within specialized work areas.

Long Term Benefits of Industrial Safety Padding

Organizations that invest in industrial safety padding experience measurable safety and operational advantages. Properly installed industrial safety padding helps reduce workplace injuries, improves technician comfort, and supports employee productivity during extended maintenance or manufacturing tasks. Cleanroom approved materials also allow industrial safety padding to support contamination control requirements while protecting sensitive equipment from accidental impact. With professional engineering support and custom fabrication capabilities, industrial safety padding provides long lasting ergonomic protection that supports facility performance and workforce safety across multiple industries. Contact Pro-Fab today to learn how custom industrial safety padding solutions can improve safety, comfort, and compliance in your cleanroom or manufacturing environment.