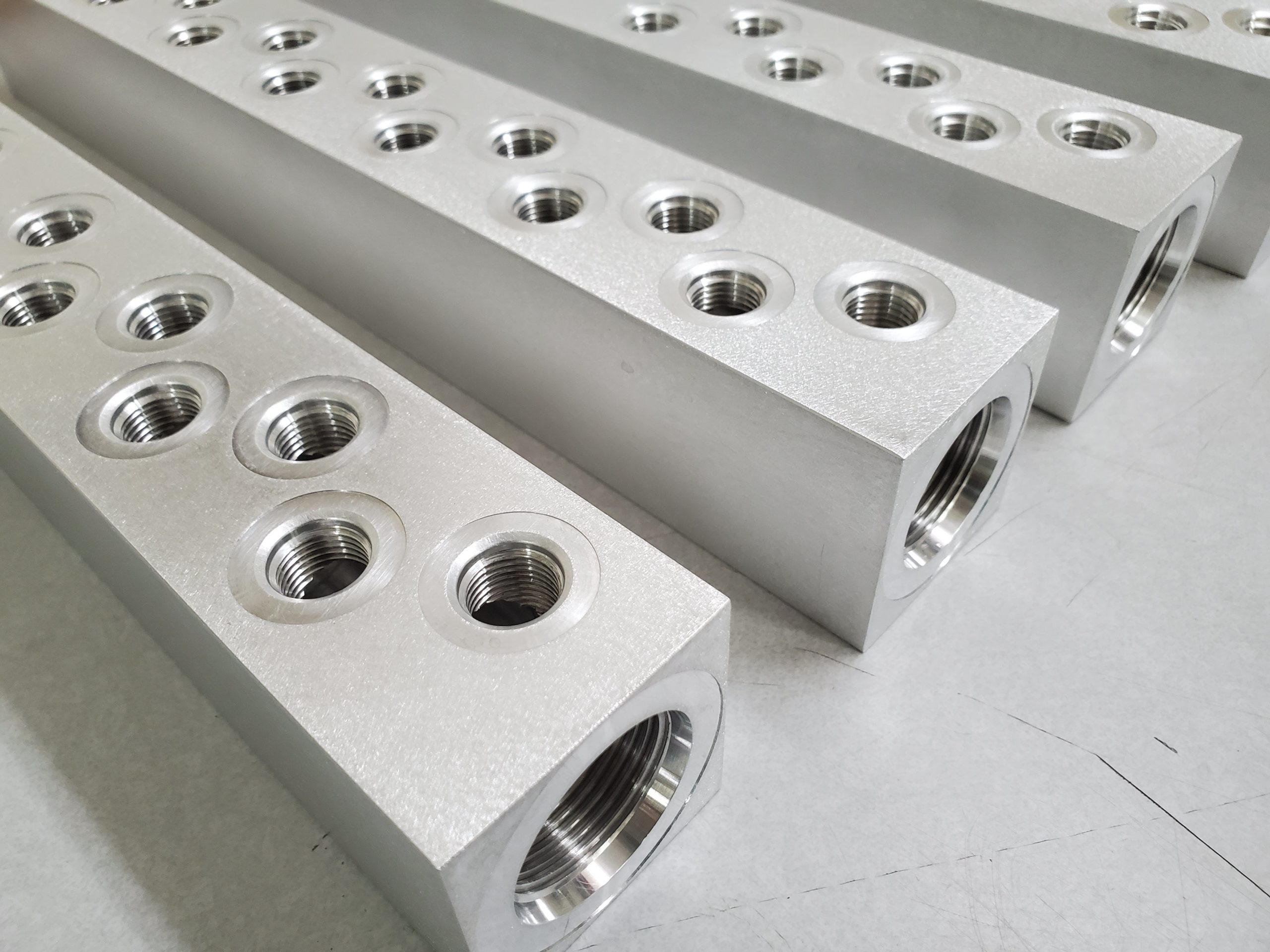

Metal Fabrication

Metal fabrication is the process of creating metal structures or parts by cutting, bending, and assembling metal materials. It is a versatile process that can be used to create a wide variety of products, from simple brackets to complex machinery and parts. At Pro-Fab, we use metal fabrication to provide for a wide range of industries, including cleanroom industries, manufacturing, and defense manufacturing. Stainless steel is a popular choice for metal fabrication due to its strength, durability, and corrosion resistance. Two of the most common grades of stainless steel that we use in our fabrications are 304 and 316.

304 Stainless Steel

304 stainless steel is a general-purpose grade that is well-suited for a variety of applications. It is corrosion resistant in most environments, including air, water, and some chemicals. 304 stainless steel is also relatively easy to weld and machine.

316 Stainless Steel

316 stainless steel is a more corrosion-resistant grade than 304. It is often used in applications where there is exposure to chlorides, such as marine environments or swimming pools. In addition, 316 stainless steel typically costs more than the 304.

Finishing Options

There are a variety of finishing options available for stainless steel fabrication. The most common finishing options include:

- #4 Brushed Finish: This finish is created by brushing the surface of the stainless steel with a wire brush. It provides a matte finish that is both durable and aesthetic.

- Electropolished Finish: This finish is created by using an electric current to remove the microscopic imperfections from the surface of the stainless steel. It produces a mirror-like finish that is very corrosion resistant.

- Powder Coated Finish: This finish is created by applying a powder coating to the surface of the stainless steel. The powder coating is then cured at high temperature, creating a durable and weather-resistant finish.

Additional Benefits of using 304 and 316 Stainless Steel in Metal Fabrication

Stainless steel is a very strong and durable material that can withstand a lot of wear and tear. This makes it a good choice for applications where strength and durability are important, such as for machinery parts. Stainless steel is very resistant to corrosion, which makes it a good choice for applications where it will be exposed to harsh environments, such as in the marine industry or in chemical processing plants. Its sleek and modern appearance makes it a popular choice for architectural applications. It can also be finished in a variety of ways to create different looks, such as brushed, polished, or powder coated. In addition, stainless steel is 100% recyclable, which makes it a sustainable choice for metal fabrication.

Contact Pro-Fab for Your Custom Metal Fabrications

Pro-Fab is a leading custom manufacturing company that produces a wide range of products for manufacturing facilities. We can create custom solutions for your facility, including conveyor systems, material handling equipment, workstations, and storage solutions. We also have the capability to create custom solutions for your specific needs. Our team of experienced engineers and fabricators can work with you to design and fabricate the perfect solution for your manufacturing facility. Contact Pro-Fab today to learn more.